Moisture Barrier Paint For Basement Floor: A Comprehensive Guide

Basements, located below ground level, are often prone to moisture problems. This can lead to a range of issues, including mold growth, structural damage, and unpleasant odors. One solution to mitigate these concerns is the application of moisture barrier paint, specifically formulated for basement floors. This article provides a detailed examination of moisture barrier paint, its benefits, selection criteria, application process, and maintenance considerations.

Understanding Basement Moisture Issues

Before delving into the specifics of moisture barrier paint, it is crucial to understand the sources of moisture in basements. Several factors contribute to dampness, including:

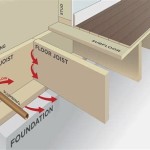

Hydrostatic Pressure: Groundwater exerts pressure against the foundation walls and floor. This pressure can force water through porous concrete or cracks, leading to water seepage.

Capillary Action: Concrete is a porous material. Water can be drawn upwards through the concrete via capillary action, similar to how water travels up a plant stem.

Condensation: Warm, humid air entering the basement can condense on cool surfaces, such as concrete floors and walls, especially during the summer months.

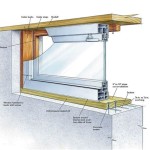

Leaks: Cracks in the foundation, improperly sealed windows, or plumbing leaks can introduce water into the basement.

Addressing these underlying moisture sources is essential for long-term effectiveness, even when utilizing a moisture barrier paint. This may involve improving drainage around the foundation, repairing cracks, and ensuring proper ventilation.

What is Moisture Barrier Paint?

Moisture barrier paint, also known as waterproof paint or concrete sealant, is a specialized coating designed to prevent water from penetrating porous surfaces like concrete. Unlike regular paint, which primarily provides aesthetic enhancement, moisture barrier paint forms a robust, impermeable layer that effectively seals the surface and resists water intrusion.

These paints typically consist of a resin base combined with additives that enhance their waterproofing properties. Common resins used in moisture barrier paints include:

Epoxy: Epoxy-based paints offer excellent adhesion, chemical resistance, and waterproofing capabilities. They form a hard, durable surface that can withstand heavy foot traffic and resist staining.

Acrylic: Acrylic-based paints are more flexible than epoxy and offer good UV resistance. They are also easier to apply and clean up, making them a popular choice for DIY projects.

Latex: Latex-based paints are water-based and have low VOC (volatile organic compounds) content. They are easy to apply and provide good moisture resistance, although they may not be as durable as epoxy or acrylic options.

The specific formulation and features of moisture barrier paint will vary depending on the manufacturer and intended application. It is important to carefully read the product label and specifications to ensure it is suitable for the specific needs of the basement floor.

Benefits of Using Moisture Barrier Paint on Basement Floors

Applying moisture barrier paint to a basement floor provides numerous benefits, contributing to a healthier, more usable living space. These benefits include:

Moisture Protection: The primary benefit is the creation of a waterproof barrier that prevents moisture from seeping through the concrete floor. This helps to keep the basement dry and prevent the growth of mold and mildew.

Mold and Mildew Prevention: Mold and mildew thrive in damp environments. By reducing moisture levels, moisture barrier paint inhibits the growth of these harmful organisms, improving indoor air quality and protecting against potential health problems.

Structural Protection: Excessive moisture can damage concrete and other building materials. Moisture barrier paint helps to protect the structural integrity of the basement by preventing water from weakening the foundation.

Odor Reduction: Damp basements often have a musty odor due to mold and mildew growth. By controlling moisture levels, the paint helps to eliminate these unpleasant odors.

Improved Energy Efficiency: A dry basement is easier to heat and cool. By preventing moisture from penetrating the floor, the paint can help to improve the energy efficiency of the home.

Enhanced Appearance: Many moisture barrier paints are available in a range of colors and finishes, allowing homeowners to enhance the aesthetic appeal of their basement floor. This can transform a damp, unfinished space into a more attractive and usable area.

Selecting the Right Moisture Barrier Paint

Choosing the appropriate moisture barrier paint is crucial for achieving optimal results. Several factors should be considered during the selection process:

Type of Resin: As mentioned earlier, epoxy, acrylic, and latex are common resin types. Epoxy offers the best waterproofing and durability, while acrylic provides good UV resistance and flexibility. Latex is a more affordable option with easier application and lower VOC content.

Surface Preparation Requirements: Different paints may require varying levels of surface preparation. Some paints may adhere well to slightly damp surfaces, while others require a completely dry surface. Consider the amount of time and effort required for surface preparation when making your selection.

Application Method: Some paints can be applied with a brush, roller, or sprayer. Consider the size of the basement floor and personal preference when choosing an application method. Sprayers can provide a more even and efficient application for large areas.

Drying Time: Drying times can vary significantly between different paints. Consider the amount of time you have available for the project and choose a paint with a drying time that fits your schedule.

VOC Content: VOCs are volatile organic compounds that can be harmful to human health. Opt for paints with low or zero VOC content to minimize indoor air pollution.

Durability and Abrasion Resistance: If the basement floor will be subject to heavy foot traffic or abrasion, choose a paint that is specifically formulated for durability and abrasion resistance. Epoxy-based paints are generally the most durable option.

Permeability Rating: Look for a paint with a low permeability rating, indicating its ability to resist water vapor transmission. This rating is typically expressed in perms (grains of water vapor per hour per square foot per inch of mercury vapor pressure difference).

Manufacturer Reputation and Reviews: Research different paint manufacturers and read online reviews to get an idea of the quality and performance of their products. Choose a reputable brand with a proven track record of providing effective moisture barrier paints.

Preparing the Basement Floor for Painting

Proper surface preparation is vital for ensuring the adhesion and performance of moisture barrier paint. The following steps should be taken to prepare the basement floor:

Remove Existing Coatings: If the floor has existing paint, sealant, or adhesive, it must be removed. This can be done using a scraper, grinder, or chemical stripper. Ensure the surface is clean and free of any loose debris.

Clean the Floor: Thoroughly clean the floor with a degreaser and water to remove any dirt, oil, or grease. Rinse the floor thoroughly and allow it to dry completely. This is critical since most moisture barrier paints will only stick if the surface is completely clean and free of any residues.

Repair Cracks and Holes: Fill any cracks or holes in the concrete with a concrete patching compound. Allow the patching compound to dry completely according to the manufacturer's instructions. This creates a smooth, even surface for the paint to adhere to.

Etch the Concrete: Etching the concrete opens up the pores of the surface, creating a better bond for the paint. This can be done using a concrete etching solution or muriatic acid. Follow the manufacturer's instructions carefully and wear appropriate safety gear, including gloves and eye protection.

Neutralize the Etching Solution: After etching, neutralize the surface with a solution of baking soda and water. Rinse the floor thoroughly with clean water and allow it to dry completely. This step is essential to remove any remaining acid residue that could interfere with the paint's adhesion.

Dry the Floor: Ensure the floor is completely dry before applying the paint. Use a moisture meter to check the moisture content of the concrete. Ideally, the moisture content should be below 4% before painting.

Applying Moisture Barrier Paint

Once the basement floor is properly prepared, the application process can begin. Follow these steps for best results:

Apply a Primer (Optional): Some moisture barrier paints recommend the use of a primer to improve adhesion and ensure a uniform finish. If using a primer, apply it according to the manufacturer's instructions and allow it to dry completely.

Mix the Paint: Thoroughly mix the paint according to the manufacturer's instructions. Some paints may require the addition of a catalyst or hardener. Stir the paint well to ensure that all components are properly mixed.

Apply the First Coat: Apply the first coat of paint using a brush, roller, or sprayer. Apply the paint evenly and avoid applying too much paint in one area. Work in small sections and overlap each stroke to ensure complete coverage.

Allow the First Coat to Dry: Allow the first coat of paint to dry completely according to the manufacturer's instructions. Drying times can vary depending on the temperature and humidity.

Apply Additional Coats: Apply additional coats of paint as recommended by the manufacturer. Multiple coats will provide better moisture protection and durability. Allow each coat to dry completely before applying the next.

Cure the Paint: Allow the paint to cure completely before using the basement floor. Curing times can vary depending on the paint type and ambient conditions. Follow the manufacturer's instructions for curing times.

Maintaining a Moisture Barrier Painted Basement Floor

Proper maintenance will help extend the lifespan of the painted floor and ensure continued moisture protection. Consider the following maintenance tips:

Regular Cleaning: Clean the floor regularly with a mild detergent and water to remove dirt and debris. Avoid using harsh chemicals or abrasive cleaners, as these can damage the paint finish.

Inspect for Damage: Regularly inspect the floor for any signs of damage, such as cracks, chips, or peeling paint. Repair any damage promptly to prevent moisture from penetrating the concrete.

Address Water Leaks: If any water leaks are detected, address them immediately to prevent moisture buildup and potential damage to the floor.

Reapply Paint as Needed: Over time, the paint may wear down or become damaged. Reapply paint as needed to maintain a continuous moisture barrier.

Use Protective Mats: In high-traffic areas, use protective mats or rugs to prevent wear and tear on the painted surface.

Ghostshield Moisture Vapor Barrier 3 Gal Clear High Gloss 2 Part Interior Concrete Basement And Garage Floor Paint Coating 440

Kilz Basement Masonry Waterproofer

Moisture Vapor Barrier For Concrete Floors In Oregon

Ghostshield Moisture Vapor Barrier 3 Gal Clear High Gloss 2 Part Interior Concrete Basement And Garage Floor Paint Coating 440

Ghostshield Moisture Vapor Barrier 3 Gal Clear High Gloss 2 Part Interior Concrete Basement And Garage Floor Paint Coating 440 The Home

Cmw 8000 Lithium Moisture Vapor Barrier And Concrete Densifier

Underslab Retrofits Sealing Slabs Waterproof Magazine

Do This Before Laying Carpet In Your Basement

Are Vapor Retarders Necessary For Basement And Garage Floors

Mv2112 Moisture Vapor Barrier Primer For Concrete Floors Astm F3010

Related Posts