Best Waterproof Coating For Basement Walls

Basement waterproofing is a crucial aspect of home maintenance, especially for properties located in areas prone to high water tables, frequent rainfall, or poor drainage. Untreated basement walls can lead to significant structural damage, mold growth, and unhealthy living conditions. Applying a waterproof coating is a common and effective method to mitigate these risks. Selecting the appropriate coating is vital for long-term protection. This article surveys various types of waterproof coatings suitable for basement walls, highlighting their properties, advantages, and disadvantages, to aid in making an informed decision.

The primary function of a waterproof coating is to create a barrier that prevents water from penetrating the basement walls. This barrier can protect against hydrostatic pressure, which is the force exerted by groundwater against the foundation. Effective coatings also resist the growth of mold and mildew, contributing to a healthier indoor environment. The choice of coating depends on several factors, including the type of basement wall (concrete, cinder block, etc.), the severity of the water problem, and budget considerations.

Understanding Common Types of Waterproof Coatings

Several types of waterproof coatings are available for basement walls, each with its own unique properties and applications. Understanding the differences between these options is essential for selecting the most suitable one for a specific situation.

Cementitious Waterproofing: Cementitious coatings are among the most widely used options for basement waterproofing. These coatings are typically composed of cement, sand, and proprietary additives that enhance their waterproofing capabilities. They are applied as a slurry or mortar to the interior or exterior surface of the basement wall.

Advantages: Cementitious coatings offer several notable benefits. They are relatively inexpensive compared to other waterproofing solutions, making them an attractive option for budget-conscious homeowners. They are also easy to apply, requiring minimal specialized equipment. Furthermore, cementitious coatings exhibit excellent adhesion to concrete and masonry surfaces, providing a durable and long-lasting waterproof barrier.

Disadvantages: While cementitious coatings are effective, they do have limitations. They can be relatively rigid and may crack if the underlying wall shifts or settles. Additionally, they may not be as effective in situations with high hydrostatic pressure, requiring additional waterproofing measures. Their effectiveness can also be compromised if applied incorrectly or to a poorly prepared surface.

Acrylic Waterproofing Coatings: Acrylic coatings are polymer-based materials that form a flexible, waterproof membrane when applied to basement walls. These coatings are typically available in liquid form and can be applied by brush, roller, or spray.

Advantages: A key advantage of acrylic coatings is their flexibility. This allows them to accommodate minor movements and cracks in the basement wall without compromising the waterproof barrier. Acrylic coatings are also generally resistant to ultraviolet (UV) degradation, making them suitable for both interior and exterior applications. They are also breathable, allowing water vapor to escape from the wall, preventing moisture buildup and potential mold growth.

Disadvantages: Compared to cementitious coatings, acrylic coatings can be more expensive. They may also require multiple coats to achieve the desired level of waterproofing. Surface preparation is critical for acrylic coatings, as they require a clean, dry, and properly primed surface for optimal adhesion.

Epoxy Coatings: Epoxy coatings are thermosetting polymers that form a highly durable and chemical-resistant waterproof barrier. They are typically composed of two components (resin and hardener) that must be mixed together before application.

Advantages: Epoxy coatings offer exceptional resistance to water penetration and chemical attack, making them suitable for basements with high levels of moisture or potential exposure to chemicals. They also provide a hard, durable surface that can withstand abrasion and impact. Epoxy coatings are often used in industrial and commercial settings due to their robust performance characteristics. They also have good adhesion to concrete and masonry surfaces.

Disadvantages: Epoxy coatings can be more expensive and more challenging to apply than other types of waterproof coatings. They require meticulous surface preparation and precise mixing of the two components to ensure proper curing and adhesion. Epoxy coatings can also be less flexible than acrylic coatings, potentially leading to cracking if the underlying wall experiences significant movement. They may also release volatile organic compounds (VOCs) during application, requiring proper ventilation.

Polyurethane Coatings: Polyurethane coatings are another type of polymer-based waterproofing material that offers excellent flexibility and durability. They are often used in applications where significant movement or expansion and contraction of the substrate is expected.

Advantages: Polyurethane coatings are highly flexible, allowing them to accommodate significant movement and cracking in the basement wall. They also offer excellent resistance to water penetration, chemicals, and abrasion. Polyurethane coatings can be applied to a variety of surfaces, including concrete, wood, and metal. They are also known for their long-term durability.

Disadvantages: Polyurethane coatings can be relatively expensive compared to other waterproofing options. They may also require specialized equipment for application, such as a plural-component sprayer. Polyurethane coatings can be sensitive to moisture during application and curing, requiring careful attention to environmental conditions. They may also yellow over time when exposed to UV light, making them less suitable for exterior applications unless a UV-resistant topcoat is applied.

Key Considerations for Selecting a Waterproof Coating

Choosing the right waterproof coating for basement walls requires careful consideration of several factors. Evaluating these factors will help ensure that the chosen coating provides effective and long-lasting protection.

Type of Basement Wall: The type of material used to construct the basement wall is a primary consideration. Concrete, cinder block, and brick all have different properties that can affect the adhesion and performance of a waterproof coating. For example, porous materials like cinder block may require a primer or sealant to reduce water absorption before applying the coating.

Severity of Water Problem: The extent of the water problem in the basement is another important factor. If the basement experiences frequent flooding or high hydrostatic pressure, a more robust waterproofing system, such as epoxy or polyurethane coating, may be necessary. For minor moisture issues, a cementitious or acrylic coating may suffice.

Application Method: The ease of application is a practical consideration. Some coatings, like cementitious coatings, can be applied with basic tools, while others, like polyurethane coatings, may require specialized equipment. The applicators skill level and available resources will influence the choice of coating.

Budget: The cost of the coating is an inevitable consideration. Cementitious coatings are typically the least expensive, while epoxy and polyurethane coatings tend to be more costly. It is crucial to balance the cost of the coating with its performance characteristics and long-term durability.

Warranty: Look for coatings that come with a warranty. A warranty provides assurance that the manufacturer stands behind its product and will cover any defects or failures within a specified period. Review the warranty terms carefully to understand the coverage and limitations.

Proper Surface Preparation for Waterproof Coatings

Regardless of the type of waterproof coating chosen, proper surface preparation is crucial for ensuring optimal adhesion and performance. Inadequate surface preparation can lead to premature coating failure, compromising the effectiveness of the waterproofing system.

Cleaning: The basement wall must be thoroughly cleaned to remove any dirt, dust, grease, oil, or other contaminants. This can be achieved by scrubbing the wall with a stiff brush and a cleaning solution, followed by rinsing with clean water. A pressure washer can be used for more stubborn dirt and grime.

Repairing Cracks and Holes: Any cracks, holes, or other imperfections in the basement wall must be repaired before applying the waterproof coating. Small cracks can be filled with a concrete patching compound, while larger cracks may require more extensive repairs. Holes should be filled with a non-shrink grout or mortar.

Removing Existing Coatings: If there are any existing coatings on the basement wall, they should be removed before applying the new waterproof coating. This can be achieved by scraping, sanding, or using a chemical stripper. Removing existing coatings ensures that the new coating adheres directly to the wall substrate.

Etching or Profiling: Concrete surfaces should be etched or profiled to create a rough texture that promotes adhesion. This can be achieved by using a chemical etching solution or by mechanically grinding the surface. The resulting surface profile provides a greater surface area for the coating to bond to.

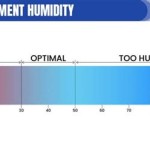

Drying: After cleaning and preparing the surface, it must be thoroughly dried before applying the waterproof coating. Moisture can interfere with the adhesion and curing of the coating. Allow the wall to dry completely, or use fans or dehumidifiers to speed up the drying process.

In conclusion, selecting the best waterproof coating for basement walls requires a comprehensive understanding of the different coating types, their advantages and disadvantages, and the specific conditions of the basement. Proper surface preparation is also essential for ensuring the long-term effectiveness of the waterproofing system. By considering these factors, homeowners can make informed decisions and protect their basements from water damage.

Advances In Spray Applied Basement Coatings Waterproof Magazine

Best Basement Waterproofing Methods Ecobuild

Waterproofing Basement Walls With Drylok Paint Home Repair Tutor

Waterproofing Basement Walls Dos And Don Ts To Remember Bob Vila

Ames Block And Wall 1 Gal Liquid Rubber Waterproof Sealant Bwrf1 The Home

The Case Against Waterproof Paints Wall Coatings Why Fail What To Do Instead

The Case Against Waterproof Paints Wall Coatings Why Fail What To Do Instead

Waterproofing Basement Walls Mission Impossible Bob Vila

Advances In Spray Applied Basement Coatings Waterproof Magazine

The Case Against Waterproof Paints Wall Coatings Why Fail What To Do Instead

Related Posts