Best Liquid Waterproofing Membrane For Basement Walls

Water intrusion can be a significant problem for basements, leading to structural damage, mold growth, and a generally unpleasant living environment. Addressing this issue proactively with effective waterproofing solutions is crucial for maintaining the integrity and usability of below-grade spaces. Among the various waterproofing methods available, liquid waterproofing membranes have gained considerable popularity due to their versatility, ease of application, and ability to create a seamless, protective barrier. Selecting the best liquid waterproofing membrane for basement walls involves careful consideration of several factors, including the type of membrane, the specific conditions of the basement, and the application process.

This article delves into the characteristics of liquid waterproofing membranes, exploring different types available and outlining the key considerations for choosing the most suitable option for basement wall applications. Understanding these aspects will enable homeowners and contractors to make informed decisions and implement effective waterproofing strategies.

Understanding Liquid Waterproofing Membranes

Liquid waterproofing membranes, as the name suggests, are applied in liquid form and cure to form a continuous, elastomeric barrier that prevents water from penetrating the substrate. These membranes are typically composed of polymers, such as asphalt, polyurethane, acrylics, or modified rubbers, combined with fillers, additives, and solvents or water as a carrier. The application process generally involves brushing, rolling, or spraying the liquid onto the prepared surface, allowing it to dry and cure into a flexible, watertight layer.

The key advantage of liquid waterproofing membranes lies in their ability to create a seamless barrier, eliminating the joints and seams that are inherent in sheet-based waterproofing systems. This seamlessness significantly reduces the risk of water infiltration through weak points, providing superior protection against moisture penetration. The elastomeric nature of these membranes also allows them to accommodate minor movements and cracks in the substrate without compromising their waterproofing integrity.

Furthermore, liquid waterproofing membranes can be applied to complex shapes and irregular surfaces, making them suitable for a wide range of basement wall configurations. They can be used on both interior and exterior surfaces, although exterior applications typically require more robust formulations to withstand environmental exposure.

Types of Liquid Waterproofing Membranes

Several types of liquid waterproofing membranes are available, each with its own set of properties, application methods, and performance characteristics. Understanding the differences between these types is essential for selecting the most appropriate membrane for a specific basement waterproofing project.

Asphalt-Based Membranes: These are among the oldest and most widely used liquid waterproofing membranes. They are typically composed of asphalt emulsions or cutback asphalts and are known for their excellent waterproofing properties and relatively low cost. Asphalt-based membranes are generally applied in multiple coats to achieve the desired thickness and are suitable for both above-grade and below-grade applications. However, they may be susceptible to degradation from UV exposure and can become brittle over time, especially in colder climates. Modified asphalt membranes, which incorporate polymers such as styrene-butadiene-styrene (SBS) or atactic polypropylene (APP), offer improved flexibility, durability, and UV resistance.

Polyurethane Membranes: Polyurethane liquid membranes are high-performance waterproofing materials known for their excellent elasticity, durability, and chemical resistance. They are typically two-component systems that require mixing before application and cure to form a tough, flexible film that can withstand significant movement and stress. Polyurethane membranes are suitable for both interior and exterior applications and are often used in areas subject to high levels of moisture or chemical exposure. However, they tend to be more expensive than asphalt-based membranes and may require specialized equipment and expertise for proper application. They are also sensitive to moisture during their curing time, which can potentially compromise the membrane's integrity.

Acrylic Membranes: Acrylic liquid membranes are water-based systems that are easy to apply and offer good adhesion to a variety of substrates. They are typically single-component systems that can be applied by brush, roller, or spray and cure by evaporation. Acrylic membranes are known for their flexibility, UV resistance, and low odor, making them suitable for interior applications. However, they may not be as durable or water-resistant as polyurethane or modified asphalt membranes, and they may be susceptible to damage from prolonged exposure to standing water.

Cementitious Membranes: While not strictly liquid in their initial form, cementitious waterproofing membranes are worth mentioning due to their widespread use in concrete structures. They consist of a blend of cement, aggregates, and polymers that are mixed with water to form a slurry or paste. This mixture is then applied to the concrete surface, where it hardens to create a dense, waterproof layer. Cementitious membranes are known for their excellent adhesion to concrete, their ability to resist hydrostatic pressure, and their compatibility with various concrete repair materials. They are typically used in conjunction with other waterproofing systems to provide enhanced protection against water infiltration.

Silicone Membranes: Silicone liquid membranes offer excellent UV resistance, flexibility, and low-temperature performance. They are often used in roofing applications but can also be used for waterproofing basement walls, particularly in areas with extreme temperature variations. Silicone membranes are typically single-component systems that are easy to apply and cure to form a durable, waterproof barrier. However, they can be relatively expensive and may not adhere well to all substrates without proper priming.

Key Considerations for Choosing a Liquid Waterproofing Membrane

Selecting the best liquid waterproofing membrane for basement walls requires careful consideration of several factors to ensure optimal performance and long-term protection. These factors include the specific conditions of the basement, the type of substrate, the application process, and the desired performance characteristics of the membrane.

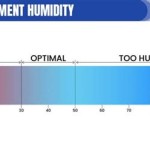

Basement Conditions: The severity of the moisture problem in the basement is a major factor in determining the type of liquid waterproofing membrane to use. If the basement is subject to hydrostatic pressure (due to a high water table), a membrane with high resistance to water penetration is essential. The temperature and humidity levels in the basement can also affect the curing time and performance of certain membranes. For instance, polyurethane membranes may require specific temperature and humidity conditions to cure properly. Furthermore, consider the presence of existing mold or mildew, as this will require pre-treatment before applying the membrane.

Substrate Type: The type of material that the basement walls are made of (e.g., concrete, concrete block, brick) will influence the choice of membrane. Some membranes adhere better to certain substrates than others, and proper surface preparation is crucial for ensuring good adhesion. Porous substrates may require priming or sealing before applying the membrane to prevent excessive absorption and ensure a uniform coating thickness. Consider if the wall surface is smooth or rough also. Rough surfaces may require more membrane to achieve adequate coverage and a uniform thickness.

Application Process: The ease of application of the liquid waterproofing membrane is another important consideration, especially for DIY projects. Single-component membranes are generally easier to apply than two-component systems, which require mixing before application. The application method (brush, roller, or spray) will also depend on the type of membrane, the size of the area to be waterproofed, and the desired finish. Consider the required curing time and the number of coats needed to achieve the desired thickness and performance. Some membranes require multiple coats to provide adequate protection, which can increase the overall project time and cost. Ensure proper ventilation during and after application, especially with solvent-based membranes.

Performance Characteristics: The desired performance characteristics of the liquid waterproofing membrane, such as its elasticity, durability, UV resistance, and chemical resistance, should be carefully considered. Elasticity is important for accommodating minor movements and cracks in the substrate, while durability is essential for long-term protection against wear and tear. UV resistance is important for exterior applications, while chemical resistance may be necessary in areas subject to exposure to harsh chemicals. Check manufacturer certifications and test data to verify the membrane's performance claims. Look for certifications from reputable organizations that attest to the membrane's waterproofing capabilities and durability. Consider also the membrane's breathability. While waterproofing is essential, allowing some degree of moisture vapor transmission can help prevent moisture buildup within the wall, which can lead to mold growth and other problems. A breathable membrane will allow moisture to escape while preventing liquid water from entering.

Cost: The cost of the liquid waterproofing membrane, including the material cost and the cost of application, should be considered in relation to its performance and durability. While it may be tempting to choose the cheapest option, it is important to consider the long-term cost of repairs and replacements if the membrane fails prematurely. Investing in a high-quality membrane with a longer service life can often be more cost-effective in the long run. Get quotes from multiple suppliers to compare prices and ensure you are getting the best value for your money. Consider the cost of any necessary primers, sealers, or other surface preparation materials, as these can add to the overall project cost.

In conclusion, selecting the optimal liquid waterproofing membrane for basement walls demands a comprehensive understanding of the diverse membrane types available and a meticulous evaluation of the specific conditions and requirements of the project. By carefully considering these factors, homeowners and contractors can make informed decisions and implement effective waterproofing solutions that will protect basements from water damage for years to come.

Dampproofing And Waterproofing For Foundation Walls Fine Homebuilding

Fluid Applied Concrete Waterproofing Liquid W R Meadows

Advances In Spray Applied Basement Coatings Waterproof Magazine

Foundation Waterproofing How To Waterproof Walls

Liquid Applied Below Grade Waterproofing Best Practices For Working With Stpe Construction Specifier

Advances In Spray Applied Basement Coatings Waterproof Magazine

Dampproofing And Waterproofing For Foundation Walls Fine Homebuilding

Exterior Foundation Coating Products For Waterproofing Concrete Network

Waterproofing Basement Floor Slabs And Walls Waterproof Magazine

The Art And Science Of Waterproofing Icf Builder Magazine

Related Posts